Replacements & CAD/CAM

Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) has a starring role in producing the likes of automobiles, office buildings, satellites and dental prosthetics.

Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) has a starring role in producing the likes of automobiles, office buildings, satellites and dental prosthetics.

Widely used in designing original jewelry, CAD/CAM can also come into play for jewelry replacements.

Jewelry retailers like to exaggerate how difficult replacements are. That idea persuades customers that the jewelry they’re buying is unique (and uniquely valuable) and deters them from comparison shopping; it also prompts insurers to believe that only the original seller can produce a replacement.

As we’ve discussed in earlier newsletters, the vast majority of jewelry is not unique, not handmade, and not irreplaceable. Most jewelry is made of prefabricated parts, such as semi-mounts ordered from suppliers’ catalogs. If manufacturer and style number were disclosed on the appraisal, the jewelry could be easily replaced.

But even for unusual jewelry, complex pieces that didn’t come from a catalog or known manufacturer, a cost-effective replacement is possible.

But even for unusual jewelry, complex pieces that didn’t come from a catalog or known manufacturer, a cost-effective replacement is possible.

The lost ring pictured at top looks complex. To an underwriter or adjuster, it may look unique and irreplaceable. But not so to a gemologist with sufficient information about the jewelry and an understanding of CAD/CAM.

“Sufficient information” means photos of the jewelry and a detailed appraisal, giving weights, grades, etc.

Jewelry photos

This submission included photos of the jewelry from three different angles. A single photo may not reveal enough, but together the three views give a good idea of the ring’s design.

The photos were probably taken by the insured or the agent with a smart phone. The quality needn’t be what you’d expect to see in a jewelry ad. The photos should just be sufficiently clear and taken from enough angles to show the look of the jewelry.

Detailed appraisal

A good appraisal includes all the details specified in JISO 78 appraisal, giving a complete description of the gemstones and the mounting.

The appraisal for the ring shown here was very complete. Using the detailed description of the main diamond, the replacement gemologist could search for a stone that closely matched the lost stone in color, clarity, carat weight and cut proportions.

The appraisal also gave the main stone’s dimensions in millimeters, which many appraisals simply omit. Using the measurements of the main diamond, along with the photos, it was possible to calculate the thickness of the band and the spacing of the pieces holding the smaller stones.

CAD/CAM

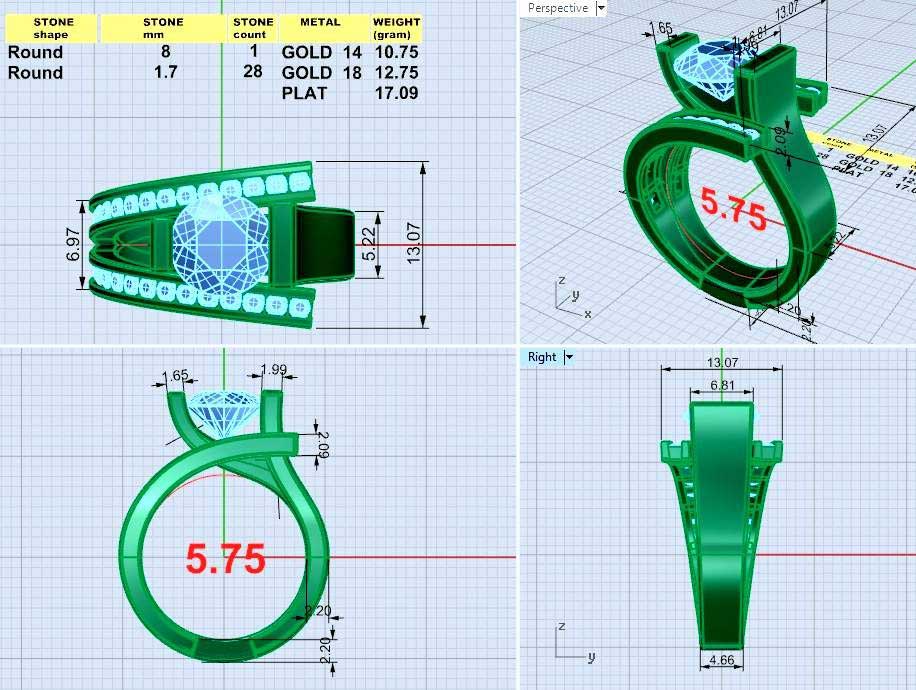

The CAD software produces 3D images allowing the ring to be viewed from any angle. This printout shows the ring from four angles, with the specific measurements for each part.

The upper left quadrant gives the weight of metals that might be used. The appraisal said the original ring was 14 karat gold. Knowing the exact amount of 14k gold required helps the gemologist calculate the final cost of the replacement.

The CAD software also produces photo-like images, showing how the manufactured piece will look. Before the replacement is actually made, the insured can verify that this is the appearance of the original jewelry.

If some little thing is not quite right, adjustments can easily be made at this stage. (Even large changes can easily be made with CAD/CAM—which is useful for designers making custom jewelry for clients. However, replacements must only duplicate the original, not alter it.)

The final precise measurements, as noted in the CAD images, are then used by CAM to make the piece of jewlery.

To make a ring like this without CAD/CAM would mean hiring a professional jewelry designer to hand-draft the drawings and laboriously work out the measurements, then have the piece manufactured using traditional machining tools. Obviously that would be extremely time-consuming and would be prohibitively expensive for insurers needing a replacement.

With jewelry CAD/CAM services in the mix, insurers are able to have replacements made for unusual or complex jewelry at prices within policy limits.

FOR AGENTS & UNDERWRITERS

Every submission for scheduled jewelry should include all information needed for an accurate replacement: a detailed appraisal (as found on JISO appraisals) and photos of the jewelry, generally 3 or more photos from different angles.

Suitable photos can easily be taken with today’s smart phones. It is best to have the photos in jpg format, as printed photos lose much detail.

FOR ADJUSTERS

Do not assume that the jewelry is not reproducible. For complex pieces, consider seeking out a replacement service experienced in CAD/CAM.

On a damage claim, ALWAYS have the jewelry examined in a gem lab that has appropriate equipment for the job and is operated by a trained gemologist (GG, FGA+or equivalent), preferably one who has additional insurance appraisal training, such as a Certified Insurance Appraiser™.

©2000-2025, JCRS Inland Marine Solutions, Inc. All Rights Reserved. www.jcrs.com